A History of Leadership & Innovation

What started with innovative brothers testing out a new kind of construction has grown into a company with more than 700 projects worldwide in its portfolio, featuring a broad range of highly successful industrial and commercial turnkey projects.

-

2021

2021:A growing portfolio

The company's 2021 annual report highlights big moments from the year, including two project profiles, the fabrication team's record-breaking year, and a new collaboration with Japanese company Kajima.

Learn more -

2020

2020:An expanded scope of services

Dome Technology continues to increase in expertise. Structural-steel fabrication, including stair towers, work towers, conveyor supports, handrails, and walkways, can be built by the team. “We’re tied closely to the dome, so we know what (customers) want, and we know how everything interfaces,” said Dome Technology shop operations manager Kirby Sheldon. “We’ll see problems other fabricators won’t see.”

Learn more -

2018

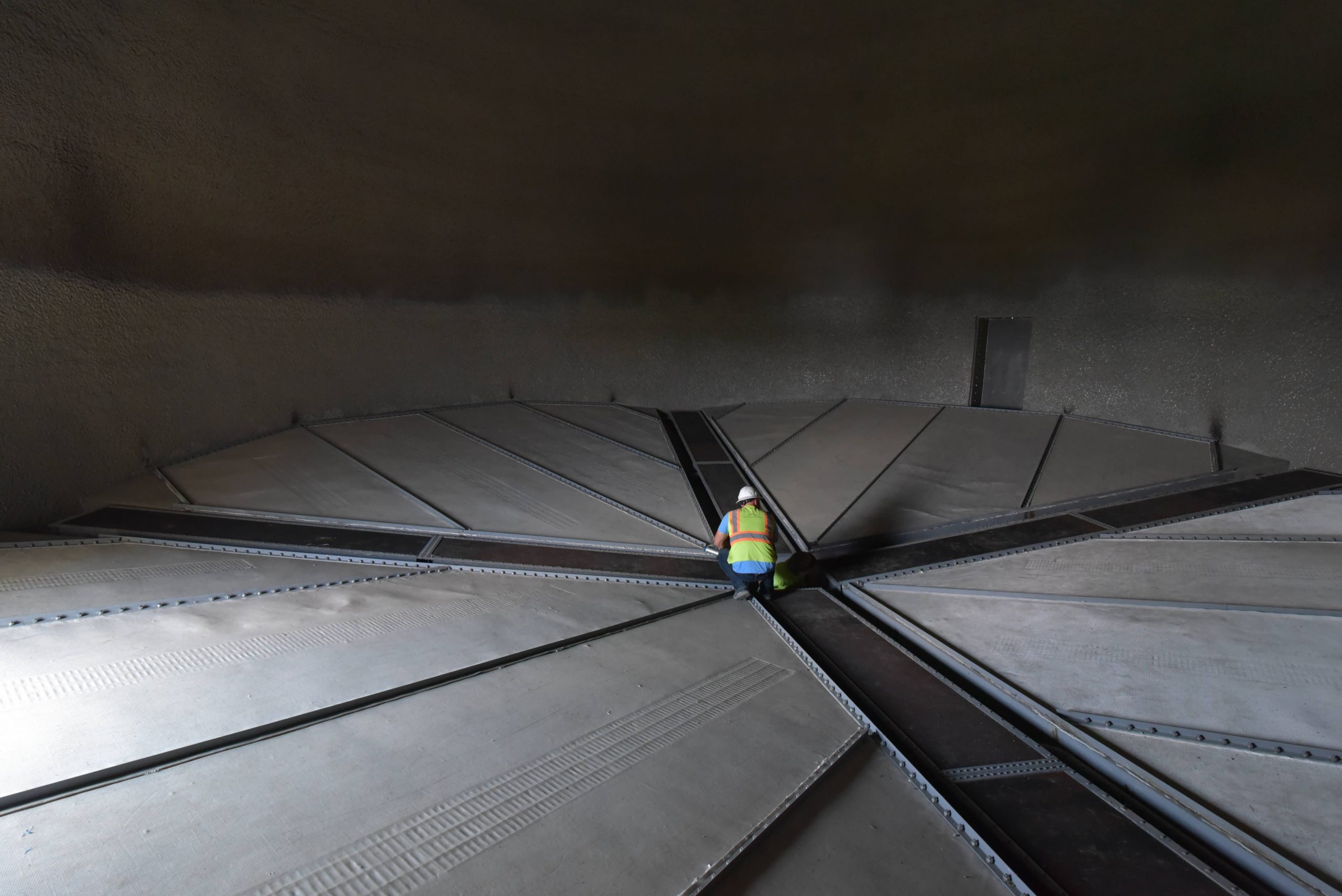

2018:First Drive-Thru DomeSilo built in Memphis, Tennessee, USA for Continental Cement

The Drive-Thru delivers 100 percent live reclaim from a fully aerated floor. Product flows through a loadout spout for loading into truck. An in-line lump crusher on the loadout stack-up ensures that lumps passed through the receiving system do not make it into trucks. The dome can receive 350 mtph from the barge unloader and load out at 320 mtph. “The biggest advantage of a drive-thru dome is you can load directly out of the floor of the dome—you can imagine the headaches this eliminates,” Continental Cement area supervisor Dustin Whited said.

Learn more -

2016

2016:600th dome

-

2015

2015:Six coal domes built for China Coal in the inner Mongolia province

China Coal sought storage facilities for both its Hulusu and Menkeqing coalmines, located fifteen miles apart in north China’s Inner Mongolia province. Based on “their ability to keep out outside moisture,” Dome Technology CEO Bradley Bateman said a series of domes was a more economical solution than traditional silos. And in the land of the yurt, another factor “was the aesthetics; it was the way they look,” he said.

Learn more -

2014

2014:First Nuclear Regulatory Commission (NRC) FLEX dome built, in response to the Fukushima, Japan, incident – Dominion Surry Power Station, Hardy, Virginia, USA

-

2013

2013:Four wood-pellet domes built for Drax in Selby, United Kingdom — Europe’s single largest decarbonization project to date

The size and scale of the project requires unprecedented biomass storage, essentially four domes each holding 80,000 metric tons of biomass. Dome Technology’s team was responsible for the overall design of the dome system, including reclaim tunnels, floor slabs, upper and lower ring beams, dome shells, and waterproofing.

Learn more -

2012

-

2011

2011:Construction of the world’s largest concrete storage dome at 330 feet in diameter – Climax Molybdenum, Leadville, Colorado, USA

At an elevation of 3,353 meters (11,000 feet), weather conditions suitable for building would last just four months in the calendar year; since a dome’s rapid construction process is ideal for quick construction, project managers and crews maximized workdays complete the job within the workable time.

Learn more -

2010

2010:First fire station – New Mexico Spaceport Authority, Truth or Consequences, New Mexico, USA

When Spaceport America needed a fire station for its campus in Truth or Consequences, New Mexico, a modern aesthetic with a nod to the desert environment was a must. Dome Technology was contracted to build the fire station featuring an organic design that captures the feel of space exploration and complements the landscape.

Learn more -

2010

2010:First wood-pellet dome – Peeples Industries, Savannah, Georgia, USA

Despite Savannah’s soggy soils, water levels were managed and the grade brought up, allowing reclaim tunnels to be wrapped in waterproof blanket and installed underground—and that equaled space savings inside and cost savings too, said Dome Technology sales manager Lane Roberts.

Learn more -

2009

2009:500th dome

-

2008

2008:Completion of the world’s largest capacity clinker-storage DomeSilo – Lafarge Cement Romania, Medgidia, Romania

According Wieslaw Krynicki, who acted as the Lafarge project manager, the company’s main requests included capacity, durability, temperature resistance, and cost effectiveness. A dome from Dome Technology was selected “because of (its) innovative and cost-optimized solution,” he said. “All requests and expectations were fulfilled. I am rather sure that in case of similar need, Lafarge would go for the same solution.”

Learn more -

2007

2007:First 300-foot dome – ADM Cogeneration, Columbus, Nebraska, USA

Following the success of its coal dome in Clinton, Iowa, ADM needed a similar dome in Columbus, Nebraska, that could maintain a constant 60,000 short tons of coal on site. This dome reached 300 feet in diameter to provide the necessary capacity.

-

2004

-

2003

2003:400th dome

-

1999

1999:300th dome

Also, first clinker dome – Ras Al Khaimah, United Arab Emirates

-

1997

1997:First ore dome – Blytheville, Arkansas, USA

-

1994

1994:200th dome

Also, first fly-ash dome – Montreal, Quebec, Canada

-

1990

1990:First coal dome – Ebensburg, Pennsylvania

-

1989

1989:First cement dome – Newport, Minnesota, USA

-

1986

1986:100th dome

-

1983

1983:First large commercial dome – South Bend, Indiana, USA

-

1982

1982:First mineral dome – Mexico, Missouri, USA

-

1981

1981:First water tank – Provo, Utah, USA

-

1979

-

1978

1978:First fertilizer dome – Chandler, Oklahoma, USA

-

1977

1977:First grain dome – Menan, Idaho, USA

-

1976

1976:First dome built

The South brothers started with a dome-shaped fabric airform built to the size and shape of the dome. This airform became the roof membrane of the dome. It had to be strong and long lasting. The roof membrane was then bolted to a circular foundation, and the dome airform was inflated. The construction was then done from the inside. The first dome, 105’ in diameter and 35’ high, was built in Shelley, Idaho.